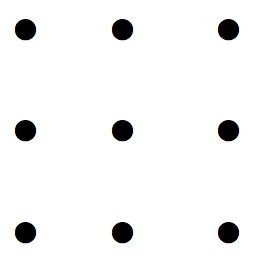

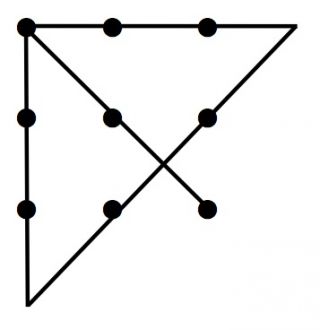

In 1926, Graham Wallas described the four stages of insight: preparation, incubation, the flash of illumination, and verification. This model of insight tries to explain how people make discoveries that get them past impasses. For example, the 9-dot puzzle challenges people to connect all the dots with only four lines, without lifting pen from paper.

It seems impossible unless we notice that we have been trapping ourselves with flawed assumptions. We don’t have to stay within the borders, and we don’t have to change directions on a dot. The impasse paradigm fits the Wallas model and is the most common method for studying insights. But this is only one form of insight.

Other types of insight don’t involve impasses and don’t require us to detect flawed assumptions. The second variety of insight hinges on spotting a contradiction – something that doesn’t make sense. For example, a police officer was once waiting for a traffic light to turn green when he noticed that the driver in the car in front of him, a new BMW, took a long drag on his cigarette and then flicked the ashes on the upholstery. That didn’t add up. Who would dirty his own car that way? Or a car he had borrowed? Now, someone who had just stolen the car wouldn’t worry about using an ashtray. The insight paid off in the pursuit and arrest of the car thief. No impasse, no advance preparation, just a troubling anomaly.

The third variety of insight involves a connection, like Charles Darwin, who read a book by Malthus on competition for scarce resources such as food, and appreciated that his theory of evolutionary changes could be driven by survival of the fittest.

This third form, the connection insight, was in the news recently, in a story about how to use mushrooms to protect the environment. This mushroom revelation also teaches us some important lessons about insights. It all started when a high school boy made an accidental observation while shoveling wood chips on his father’s maple-sugar farm in Vermont. That observation has evolved into an exciting technology for using mushrooms in place of the Styrofoam plastics we see all the time in packing peanuts and coffee cups. Styrofoam lasts almost forever, littering highways and oceans. The new mushroom technology, which is cheap to produce and safely biodegrades in a month, could easily replace Styrofoam as an insulation and packing material.

The short version of the discovery – for a fuller account see Ian Frazier’s article, Form and Fungus in The New Yorker May 20, 2013 – starts with Eben Bayer performing farm chores such as moving wood chips around. Even when the piles of wood chips were covered by a tarp, they still got wet; mushrooms would sprout and weave the chips together into clumps, making it easier for Eben to lift them with his pitchfork. Not an earth-shaking observation, not worth writing a scientific paper about. Just a passing lesson as Eben helped his father.

Fast forward a few years and Eben was attending Rensselaer Polytechnic Institute (RPI) in Troy, NY. He had been given a course assignment to make insulation panels using perlite, a mineral that comes in large granules that settle, making it hard to apply uniform coatings. It was difficult to get the perlite to clump together, which made Eben remember his wood chips. So he ordered a cheap mushroom kit and mixed the spores with perlite, adding water and nutrients to let the mushrooms sprout. In a few days he had achieved success. The mushroom strands had woven the perlite into a solid disk, the shape of the glass flask in which he had grown the mixture.

In his senior year at RPI Eben showed this disk to another professor, in a course called “The Inventor’s Studio”. Eben wasn’t sure what to do with the disk, and hoped the professor would be impressed. He was. He immediately appreciated that Eben had invented a biological polymer that could replace Styrofoam and other synthetic polymers. Growing the mushroom compound requires minimal energy – you just mix the right kinds of mushroom spores with waste products such as rice husks and corn stalks, put it in a mold to give it the shape you want, and turn off the lights. A few days later it is ready. You stop it from growing by applying heat, which kills the mushroom strands. The professor helped Eben and his partner set up a small company that has the potential to become the biological version of Dow Chemical or DuPont.

Eben didn’t run into an impasse about how to use mushrooms as a biological polymer because he wasn’t trying to invent a replacement for Styrofoam. He didn’t even understand the implications of his invention until his professor enlightened him. Wallas’ account of insight doesn’t work, at least in cases like this.

Insights don’t necessarily depend on preparation. They don’t necessarily help us get past impasses. If we want to understand insights we’ll need to broaden our perspective to take stories like this into account.